Polybind Complete

For concrete paving stones & natural stones, for joints up to 2" (5 cm)

TRADITIONAL APPLICATIONS

setting time: 1 hour above 32°F (0°C)

OVERLAY APPLICATIONS

Setting time: 24 hours above 32°F (0°C)

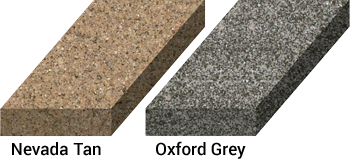

POLYBIND COMPLETE is a unique mixture of polymer binders and calibrated sand available in Beige and Slate Grey. The installation of the polymeric sand POLYBIND COMPLETE is almost identical to using regular paver joint sand except for the application of water. Once POLYBIND COMPLETE sets, it becomes very firm and locks between the paver joints while still retaining flexibility and providing a long lasting, durable jointing material. POLYBIND COMPLETE is recommended for a variety of uses including pool decks, patios, footpaths, driveways, parking spaces, pavements, etc. Offered in USA Only.

- Concrete pavers, natural stone, wet cast products and clay pavers

- Residential and commercial use

- Streetscape, commercial work, steep slope, pool areas, patios, walkways, driveways and parking areas

- Traditional applications and overlay applications

- Advanced Haze Free Technology

- Can be used for joints up to a maximum of 2 inches (5 cm)

- For overlay, traditional, residential and commercial applications

- For Traditional application, rain safe 1 hour after water activation

- For Overlay application, rain safe 24 hours after water activation

- ASTM C-144 gradation allows use in even the tightest joints

- OSHA silica crystalline compliant (OSHA 29 CFR 1926.1153)

- Can be used on false joint pavers

- Works above 32°F (0°C)

- Ideal for Gator Base panels

- Waterproof bags: Lay bag flat on its back, so front of the bag is facing you

- Helps prevent weeds and damage caused by burrowing insects

- Helps prevent erosion due to wind, rain and freeze/thaw cycles

When maintaining the paver surface, apply Gator Shampoo to clean the entire paved surface including the paver joints. Wash, rinse and remove any residue by using a hose and a watering gun set to shower with the normal maximum water pressure from any residential or commercial building (typically 80 psi/550 kPa).

Moss

POLYBIND COMPLETE will not cause nor prevent moss, mold or mildew. Moss, mold and mildew are caused by certain on site conditions including excess moisture, shade, absence of ventilation, inadequate cleaning or maintenance, presence of soil or other organic debris left on the product.

Clay Pavers

If used on clay pavers make sure they are 100% dry. Clay pavers tend to hold moisture, which can prematurely activate the POLYBIND COMPLETE while the sand is being spread over the paver surface, leaving a residue (always apply on a test area before using the POLYBIND COMPLETE on clay pavers).

| Per 50 lb (22.7 kg) bag (Paver 2-3/8″ (6 cm) in height) | NARROW JOINTS 1/8″ to 3/8″ (3-9 mm) | WIDE JOINTS 3/4″ to 1-1/4″ (19-32 mm) |

|---|---|---|

| Beige, Slate Grey | 65-85 sq. ft. (6-7.4 sq. m.) | 22-42 sq. ft. (2-3.9 sq. m.) |

| Product | Size | Units per Pallet |

|---|---|---|

| POLYBIND COMPLETE – Beige | 50 lb (22.7 kg) | 56 USA |

| POLYBIND COMPLETE – Slate Grey | 50 lb (22.7 kg) | 56 USA |

IMPORTANT INSTALLATION NOTES

- Always refer to the latest POLYBIND COMPLETE Technical Data Sheet (TDS) at AllianceGator.com before installing POLYBIND COMPLETE.

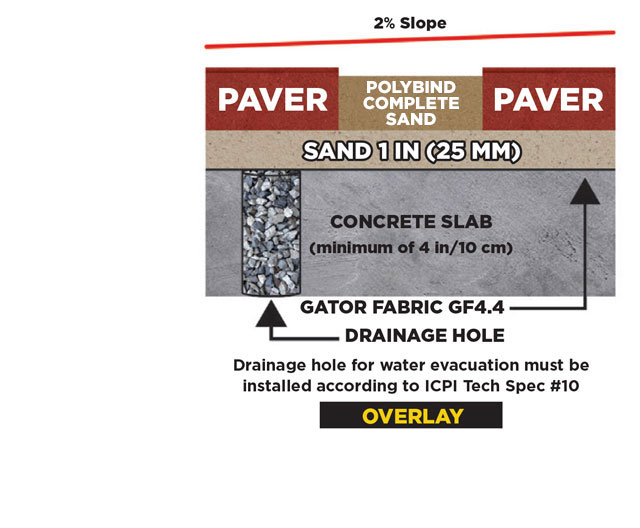

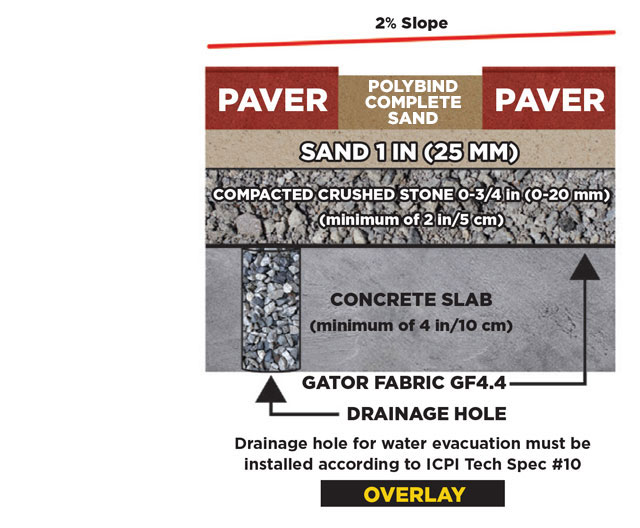

- Pavers and slabs must be installed according to ICPI Tech Spec #2 traditional application (www.icpi.org) before POLYBIND COMPLETE installation. For Overlays ICPI recommends 2″ (5 cm) diameter drainage holes spaced approximately 10 ft (3 m) apart and at the lowest elevations in the slab. Holes should be filled with #8 stone and covered with a 1 foot x 1 foot (30 cm x 30 cm) patch of Gator Fabric GF4.4. Drilled holes should allow any water entering the bedding layer to freely flow out.

- Pavers’ sides and top surfaces must be completely dry. Do not apply if the paver surface is damp or wet. The damp or wet surface will cause POLYBIND COMPLETE to prematurely activate and will lead to the polymers sticking on the paver surface.

- Do not apply if the paver joints are damp or wet. This will prevent the POLYBIND COMPLETE from properly sliding into the joints and obtaining very densely packed joints, which is critical to the products performance.

- Temperature must be above 32°F (0°C) with dry conditions (no rain for at least 1 hour) after installing POLYBIND COMPLETE in a traditional application and (no rain for at least 24 hours) in overlay application.

- For all paver surfaces, and particularly around in-ground pools there must be a slope of 1/8 inch (3 mm) per linear foot away from the edge of the pool, or structures to ensure optimal performance of the POLYBIND COMPLETE.

- For the pool coping units it is mandatory to use mortar in the joints. For the rest of the paver installation around the pool, you can use POLYBIND COMPLETE.

- Do not sweep POLYBIND COMPLETE over asphalt.

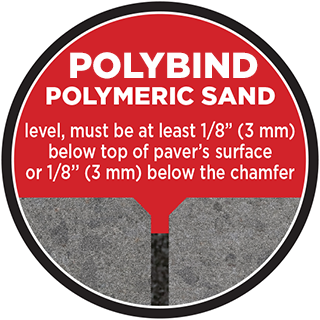

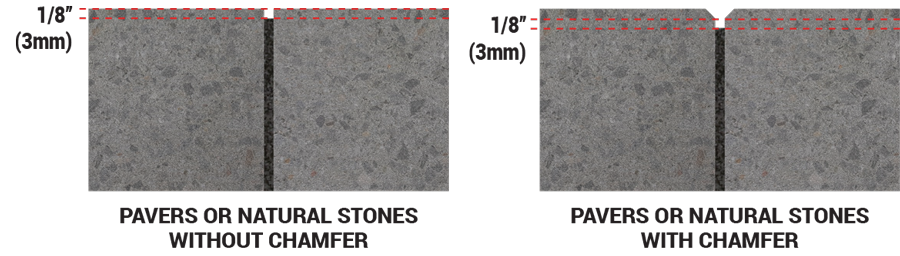

- POLYBIND COMPLETE level, must be at least 1/8 inch (3 mm) below top of paver’s surface or 1/8 inch (3 mm) below the chamfer or erosion may occur. The filled and cured polymeric sand joints should never be in direct contact with foot traffic or tires.

- For textured or pre-finished surfaces, we recommend to remove all the sand from the paver or slab surface prior to using the plate or roller compactor.

PLEASE NOTE:

All pavers must be completely interlocked for vehicular and pedestrian use. If pavers are fanned they are not considered interlocked. POLYBIND COMPLETE can be applied when pavers are installed directly on open graded aggregates that lock or choke themselves. This means the polymeric sand will not migrate through the voids. Do not apply POLYBIND COMPLETE when the pavers are installed directly on aggregates with large voids.

CROSS-SECTIONS REPRESENTS THE HEIGHT OF POLYMERIC SAND FOUND IN THE JOINTS

Maximum joint width for overlays: 2″ (5 cm)

POLYMERIC SAND REQUIREMENTS

Minimum joint width: 1/8″ (3 mm)

Maximum joint width: 2″ (5 cm)

Maximum overlay joint width: 2″ (5 cm)

Minimum joint depth: 1 1/2″ (38 mm)

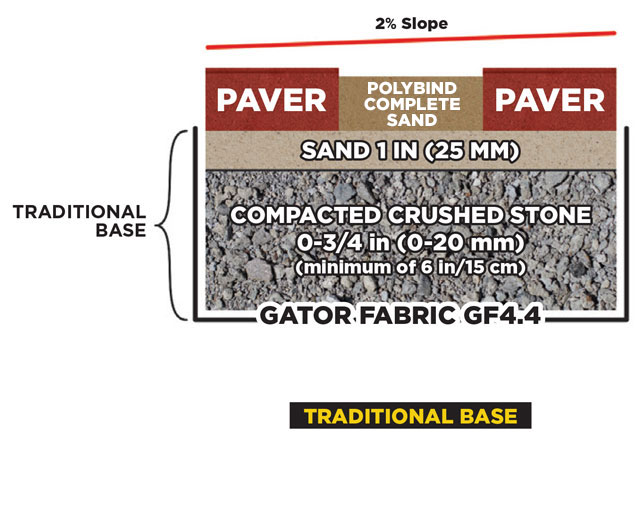

REQUIRED SUB-SURFACE PREPARATION AND FOUNDATION OPTIONS

POLYBIND COMPLETE is recommended for a variety of uses including pool decks, patios, footpaths, driveways, parking spaces, pavements etc. The concrete pavers must be installed on a traditional base system composed of 2 layers. The upper layer can have a maximum of 1 inch (25 mm) of bedding sand ASTM No.9 stone. The lower layer must have a minimum of 6 inches (15 cm) of crushed stone compacted at 98 % Proctor density. (See diagrams below).

FOR OVERLAY APPLICATIONS

- Remove all loose and fragile concrete.

- Cover bottom and side of the excavated area with a Gator Fabric GF4.4, refill with crushed stone and compact it.

Installation Instructions

(For a new paver surface)

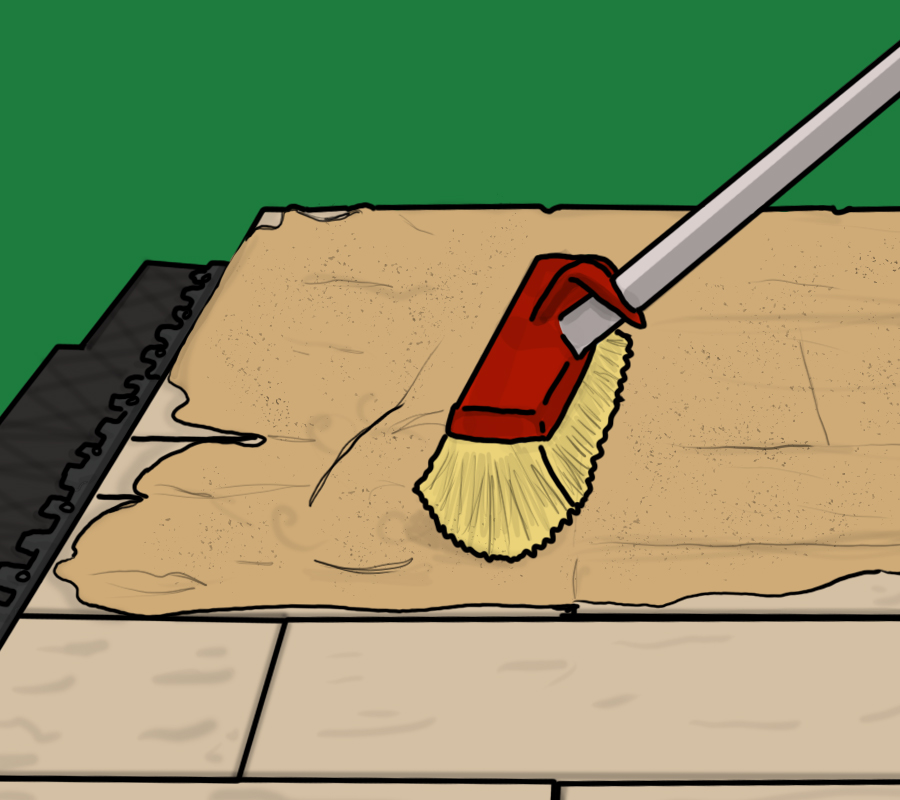

STEPS 1 & 2

Spread POLYBIND COMPLETE with hard-bristle broom. Make sure the POLYBIND COMPLETE completely fills the joints. Do not use other materials in the joints.

Leave a layer of POLYBIND COMPLETE on the surface to aid in vibrating and consolidating POLYBIND COMPLETE into joints. For textured or pre-finished surfaces, we recommend to remove all the sand from the paver or slab surface prior to using the plate or roller compactor.

STEPS 3 & 4

Vibrate the POLYBIND COMPLETE into the paver joints using a vibratory plate compactor. A rubber pad is recommended. A roller compactor is best for slab installation.

Joints sand level, must be at least 1/8 inch (3 mm) below top of paver’s surface or 1/8 inch (3 mm) below the chamfer. It is best to compact in several directions to ensure there are no air gaps or voids in the joints. Repeat steps 1-3 to ensure joints are filled and consolidated. Narrow joints require more care to completely fill.

IMPORTANT WATER ACTIVATION NOTES

- Work in manageable sections, ideally about 100 sq. ft. (10 sq. m.) at a time, depending on temperature.

- Do not allow POLYBIND COMPLETE to wash out of joint.

- Never allow paved surface to dry out during the water activation phase.

- Watering must be started at the lowest point of the paved surface.

- Use a watering gun connected to a hose. Setting should be set to shower.

STEP 9

Shower and rinse simultaneously, so as to eliminate any POLYBIND COMPLETE residue left on the same section. Any residue should go directly into the paver joints. However, stop showering when you see water retention on the paver joints. Wait no longer than 2 to 3 minutes. Proceed to STEP 10. Note: Repeat the directions of STEPS 7 to 9 for all other areas that have not been showered with water.

IMPORTANT

The water used in steps 7 to 9 will activate a bonding action as well as condensing POLYBIND COMPLETE in the joints. It is important to water the POLYBIND COMPLETE a total of 3 times, as per steps 7, 8 and 9. Too little water will not properly activate the POLYBIND COMPLETE and will reduce the final performance. If steps 7 to 10 are not done properly, a white haze may appear on paver surface after installation. This is due to excess POLYBIND COMPLETE residue left on paver surfaces. This haze will dissipate over time, or it could be removed by using Gator Clean Efflorescence Cleaner.

THE PARTIES AGREE THAT REFUND OF THE PURCHASE PRICE AS STATED IS THE ONLY OBLIGATION OF THE MANUFACTURER. IN ALL EVENTS, THE MANUFACTURER SHALL NOT BE LIABLE FOR ANY OTHER DAMAGES OR COSTS WHATSOEVER, (INCLUDING REMOVAL OR REINSTALLATION OF SAND OR PAVERS) DIRECT OR CONSEQUENTIAL. TO THE EXTENT PERMITTED BY LAW, THE MANUFACTURER EXCLUDES ANY IMPLIED WARRANTY OF QUALITY, MERCHANTABILITY OR FITNESS FOR PURPOSE. ALLIANCE DESIGNER PRODUCTS INC. excludes any responsibility whatsoever for the presence of moss, mold, mildew, or similar factors that may occur on the product after its installation. The presence of moss, mold or mildew is caused by the particular on-site conditions, including excess moisture, shade, absence of ventilation, inadequate cleaning or maintenance, presence of soil or other organic debris left on the product after installation. ALLIANCE DESIGNER PRODUCTS INC. excludes any responsibility for use of GATOR MAXX for any installation not installed to manufacturer’s specifications and ICPI Tech Spec #2.

Please note that when the product is used for other purposes (Mixed-use, commercial, institutional or other), the above terms apply except that the applicable period is reduced to 1 year from purchase. ALLIANCE DESIGNER PRODUCTS INC. excludes any responsibility for use of any Gator Polymeric Sand for any installation not installed to manufacturer’s specifications and ICPI Tech Spec #2.